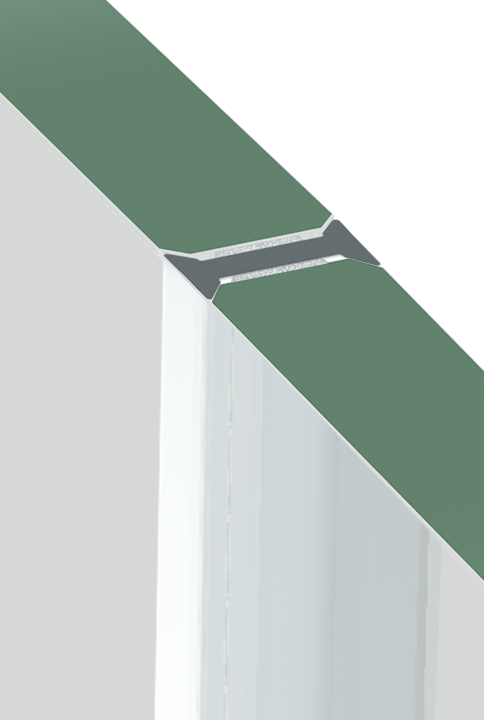

G2G – Glass Dry Joints – Installation Guide

The following points should be taken into consideration when installing G2G:

- To ensure the best bond between the G2G profile and the glass an application temperature between 18 to 35 degrees centigrade is recommended.

- It is recommended that where possible the joints and glass are equalised to room temperature 24 hours prior to fitting.

- A quality polished edge works best for maximum bond strength. When fitting the joints on site it is important that these polished edges are clean, dust and grease free.

- An alcohol wipe is recommended.

- It is essential that every panel is shimmed and plumbed (particular the first panel) vertically/horizontally and centralised in the base and head channels.

- It is recommended that prior to fitting the joint each following glass panel is placed side by side to check for bow and swapped for a flush panel if there are any showing this affect.

- It is recommended that ratchet strap/suckers are used when fitting panels to achieve the best contact pressure.

- The G2G tape has excellent initial tack and contact bond in most conditions.

- It strengthens to its maximum bond strength 12 hours after fitting.

- The compressive qualities of the G2G tape takes up some tolerance variations in the glass. This can be maximized through ensuring the glass has been cut accurately on well maintained machinery.

G2G – Glass Door Seals – Installation Guide

- A quality polished edge works best for maximum bond strength. When fitting the joints on site it is important that these polished edges are clean, dust and grease free.

- An alcohol wipe is recommended to clean the glass before fitting.

- A nominal gap of 5mm clearance is required to be left between the door leaf and the adjoining panes.

- For retrofit applications a gap of between 3.5-8mm is suitable.

- The flexible fin of the Top and Bottom seal should be lined up with the floor and then applied to the door panel.

- Where a glazed over panel is used the Side Seal should be used, at the head. When installed it should be positioned the same direction as on the leading edge.

- Trimming will be required of the side seal flippers around top and bottom hinge patches and additional hardware.

- Top and bottom seal should be fitted whilst the door is in a closed position. The top and bottom seal can accommodate a threshold gap of up to 12mm.

Please note these are for guidance only, Reddiplex take no responsibility for the overall installation of a partitioning system. All of the guidance and illustrations contained are given as guidance only and specialist advice should be sought for individual applications.