Plastic Extrusion Process

The process of plastic extrusion starts by feeding plastic granules into the hopper of the extruder. The granules are drawn down into the screw, which along with the barrel is heated and mixed. As the plastic granules move along the screw they melt and are forced through a die which is located at the end of the barrel. The die contains the cross-section of the profile for the required extrusion. The extruded profile is then cooled through water baths before being cut to length and packaged. To enhance the profile, post-extrusion techniques can be carried out such as printing, embossing and adhesion application.

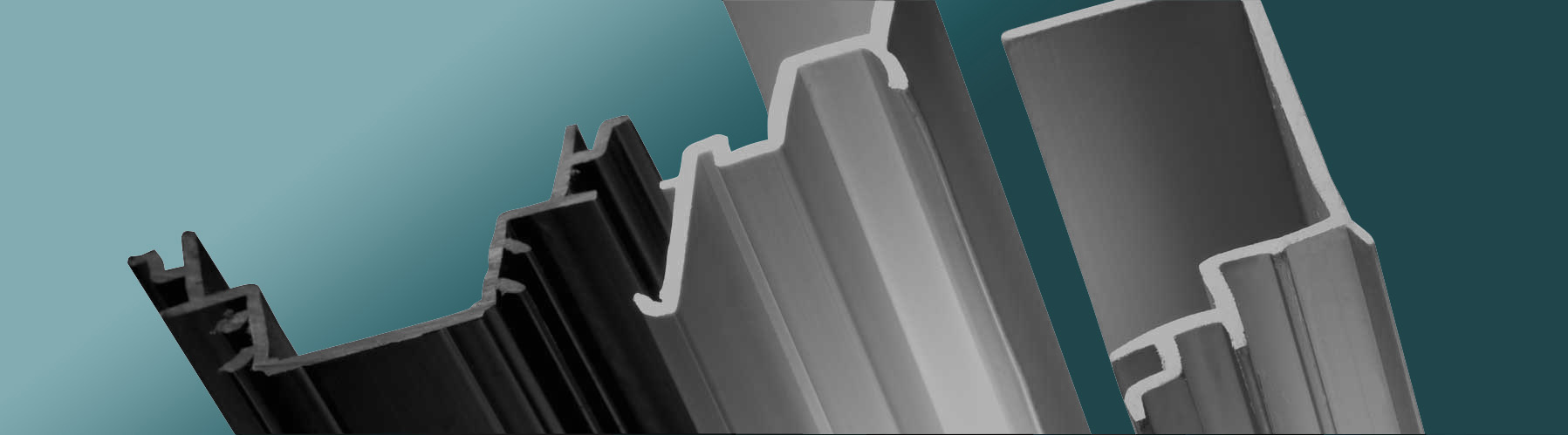

The rigid plastic profiles that we extrude are specific to our customer’s requirements. Rigid plastic extrusions are being used more frequently as a replacement for metal in automotive and construction applications. In addition, rigid profiles are suitable for visible applications as they take embossing and textures very well.

The process of plastic extrusion starts by feeding plastic granules into the hopper of the extruder. The granules are drawn down into the screw, which along with the barrel is heated and mixed. As the plastic granules move along the screw they melt and are forced through a die which is located at the end of the barrel. The die contains the cross-section of the profile for the required extrusion. The extruded profile is then cooled through water baths before being cut to length and packaged. To enhance the profile, post-extrusion techniques can be carried out such as printing, embossing and adhesion application.

The rigid plastic profiles that we extrude are specific to our customer’s requirements. Rigid plastic extrusions are being used more frequently as a replacement for metal in automotive and construction applications. In addition, rigid profiles are suitable for visible applications as they take embossing and textures very well.