Sponge Rubber Extrusion Process

Rubber profiles are extruded from the die and cured in a series of microwave units to hold their finished form. The Ballotini curing process is a very different one. On a Ballotini line the natural rubber is fed from the extruder through the die plate and then passed through a Ballotini bath. Ballotini are small pure soda lime glass balls that are heated up to approximately 220 degrees, the heat control and heat transfer makes it a perfect partnership for use with sponge compounds due to the chemical composition. This curing process results in a sponge profile that can then be packaged to the customer’s requirements.

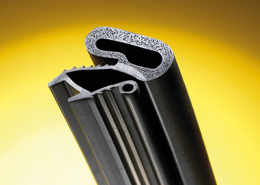

Custom Sponge Rubber Extrusions

Material: EPDM – 0.8 Sponge

Capability: Co-Extrusion

Sector: Marine

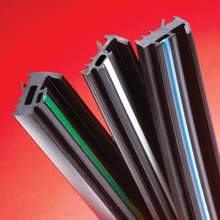

Material: EPDM – 0.4 Sponge

Capability: Single Extrusion

Sector: Drainage

Material: EPDM – 0.3 Sponge

Capability: Single Extrusion

Sector: Automotive

Sponge Densities

The following are examples of the most common sponge densities that we extrude. If you have a specific density requirement we are able to source specific for your application.

- 0.30-g/cc

- 0.40-g/cc

- 0.55-g/cc

- 0.80-g/cc