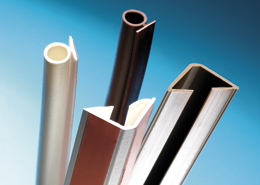

Flexible Plastic Extrusion Process

Plastic granules are fed into the hopper of the extruder and are drawn down into the screw. The barrel and screw are heated by external heating elements. As the plastic granules move along the screw they melt and are forced through a die which is located at the end of the barrel. The die contains the cross section of the profile of the extrusion required. The profile is then water cooled through water baths before being coiled and packaged.

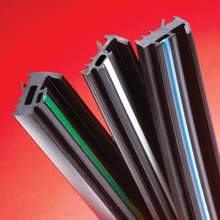

Material Types

The following are examples of the most common material types that we extrude. If you have a specific properties or material types that you require we are able to source material specific for your application.

| Name | Properties |

|---|---|

| Hytrel | High performance polyester, good fuel resistance, high temperature resistance, excellent flex fatigue resistance Excellent deflection recovery at high and low temperatures. |

| Polyurethane PU | Excellent fuel resistance, excellent flex fatigue resistance, can be modified from very flexible to very rigid, can be clear or coloured, can be formulated for very specific properties and environments. |

| PVC | Commodity material for general purpose usage and low demanding technical applications. Can be very soft or very hard, can be coloured and can be modified to enhance the technical characteristics for certain applications. |

| Nitrile PVC | Nitrile PVC is similar to normal PVC but is modified with nitrile rubber to increase the low temperature performance and the deflection recovery. |

| EVA | Commodity material with good low temperature flexibility. |

| TPE | Can be formulated to be specialist or commodity and each formulation is based on a specific technical requirement. |

| LD-PE | Flexible polyethylene, commodity material for general use with low technically demanding products, difficult to make profiles with but good for tubes. Can be coloured, has excellent chemical resistance, good low temperature impact. |