Extrusion Capabilities

The extrusion methods we offer range from single and co-extrusion, which are used for volume extrusion solutions on a regular basis, to those which are used for a much higher specification of product and involve a more complex extrusion process such as cross head extrusion.

Single hardness extrusions

Single hardness profiles are manufactured from a single material and can be flexible, rigid or rubber, which includes sponge based products.

Co-extrusion

Co-extrusion combines two different materials or colours into one single profile. Special twin head extruders and purpose made dies are used for this process.

Triplex extrusion

Triplex extrusion involves the extrusion of three different materials into one single profile. This involves highly complex machines and dies.

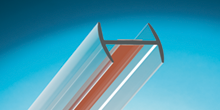

Cross head extrusion

Cross head extrusion is similar to co-extrusion but rather than combining different types of plastic or rubbers, it is possible to embed different components such as aluminium and glass fibre cord into the profile.

Pile extrusion

Extruded pile incorporates an extruded polypropylene base with either a polypropylene siliconised brush or a monofilament brush.

Material Types

Our technical and processing expertise enables us to extrude a wide range of materials, offering a custom extrusion solution specific to the individual requirements of a certain application across a wide range of market sectors.

Rigid Extrusions

Examples of material types extruded include- ABS, Nylon 66, PA, PEEK, PETg, Polycarbonate PC, Polystyrene PS, PPS-Alloy, PVC-U

Flexible Extrusions

Examples of material types extruded include- Crystal, EVE, Hytrel, LDPE, Nitrile PVC, Polyurethane PU, PVC, TPE

Solid Rubber

Examples of material types extruded include- EPDM, NBR, SBR, Neoprene, Rubber

Closed Cell Rubber

Examples of densities extruded include- 0.80 – g/cc, 0.55 – g/cc, 0.40 – g/cc, 0.30 – g/cc

In-line capabilities

Continually improving and refining our extrusion methods has enabled us to provide a series of in-line post extrusion techniques to enhance the overall aesthetics and the performance of the extrusions we manufacture.

These include:

Rolling

Application of textures or patterns to the profile.

Adhesive tape

Integrated application of adhesive tape.

Cording

To help maintain form and reduce shrinkage.

Printing

Ink-jet and laser printers can be assembled on-line; this can increase traceability, identification or brand awareness.

Colour Matching

We often work from specifications or samples to provide a colour matching service to standards such as BS and RAL.